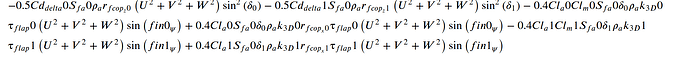

When you analyze the torques which your control surfaces generate on the CoG of your aircraft based on their deflection, you effectively applied Newtons 2nd Law:

t = f(e)

From this equation you see how each deflection, e generates torques, t in the various directions of your aircraft.

However, in controller design, you controllers outputs a torque t , and not a deflection, e, and thus the above equation needs some rework.

We need to find a way, that if we want to generate a specific amount of torque t , what is the deflection angles e needed to generate that torque. To achieve this we need to invert the above equation.

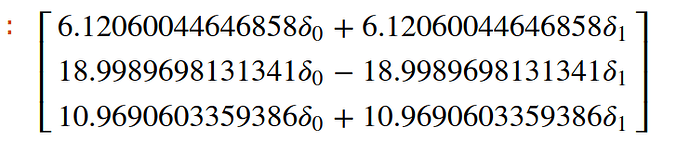

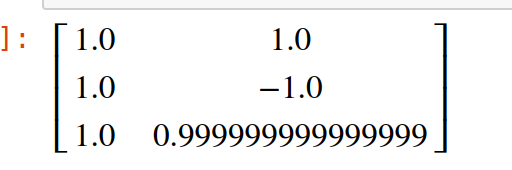

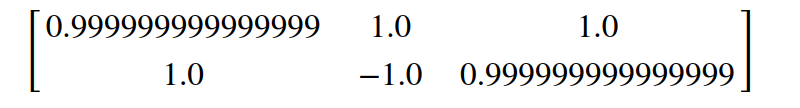

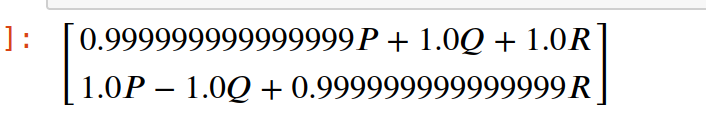

f is known as your control effectiveness equation. Usually this in a nonlinear equation, but we can linearise it, and your left with a control effectiveness matrix, F based on the various deflections.

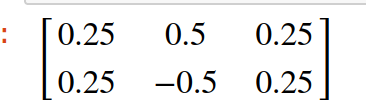

We then invert F by applying the pseudo inverse operation, to obtain F^-1 also known as the control allocation matrix

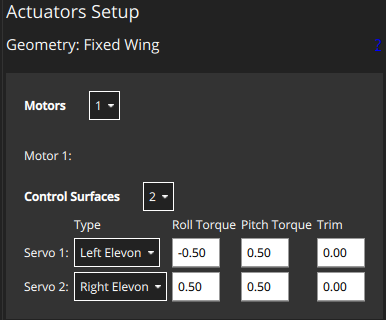

The values which you input into QGC, is the elements of the control effectiveness matrix for each deflection.

Thus the values your enter into roll, pitch and yaw, describes how effective that control surface is to influence that axis of the vehicle.

However, the important thing to remember is that the control effectiveness matrix is normalised. This usually means, that each deflection contribution in the various direction (roll, pitch, yaw) is normalised to the deflection which provides the larges torque in that axis.

Example:

You have a left elevator and right elevator. The left elevator is twice as far from the CoG as that of the right elevator. That means the torque which the left elevator will generate is twice as large. Lets say the left elevator generate 0.1 Nm per deflection angle, which means your right elevator generates 0.05 Nm per deflection angle. This means the right elevator has a effectiveness value of 0.5 and the left an effectiveness of 1.0.

This value does not mean that the control surface is effective enough to control the vehicle, but rather just a normalized value with respect to the other control surfaces which generates torques in that direction.

The amount the control surface deflect will be a linear weighted sum of the various control surfaces that can contribute to the torque being requested by the controllers. Thus the normalised value in the effectiveness matrix does tell you about the amount the control surface will deflect compared to that of the other control surfaces but it tells you also about how control surfaces can cancel out dynamics caused by other deflections. So the effectiveness matrix should not be adjusted to obtain full deflection of your ailerons, but rather comes from first principles to obtains the larges rolling torques the combine control surfaces can produce with close to zero other dynamics being generated.

When a controller request only a yaw torque, (zero pitch and zero roll), will result in the control surfaces to deflect to only generate a yawing moment (usually your rudder causes a rolling moment, and thus your ailerons would deflect to combat this rolling moment caused by the deflection of your rudder)

![]()